Industry

Pioneer

Arab Basalt Fiber Company is the Middle East and North Africa region’s largest basalt fiber and composite manufacturing facility, located in Fujairah, UAE. Through our state-of-the-art 40,173 square meter production facility, we deliver advanced material solutions across industries – from construction and automotive to renewable energy and defense applications, with planned expansion into North America and Western Europe.

Manufacturing

Champion

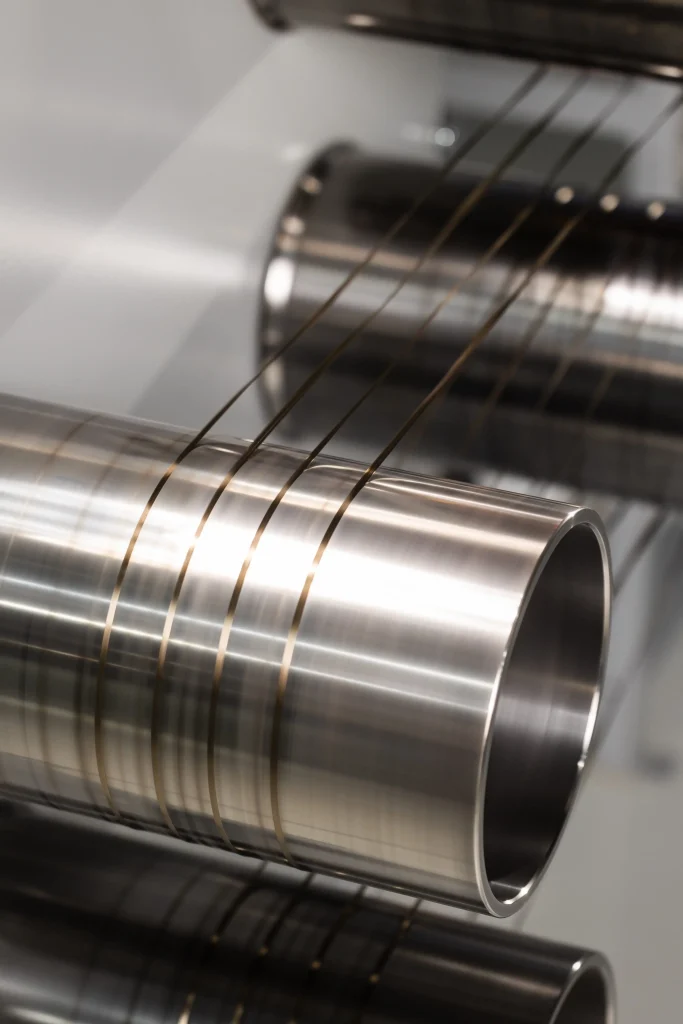

A regional champion in advanced composites and fiber solutions, our manufacturing facility processes basalt rock at temperatures between 1400–1600°C, creating high-performance materials. By 2026, our annual fiber production capacity will reach 5,000 tons, with composite rebar production expanding to 6,500 tons by 2030, supporting our projected growth to US$65 million in revenue.

Innovation and

Tech Leader

With a proven track-record in industry innovation and advanced technological solutions, we produce high-performance materials with verified tensile strength of 4,800 MPa and heat resistance up to 800°C. Fully certified to ISO 9001, 14001, and 45001 standards, our end-to-end quality control ensures excellence across all product lines

Diverse

Applications

Our advanced materials serve diverse industrial needs worldwide. From construction and automotive applications to renewable energy infrastructure and military-grade materials, our products deliver superior performance across sectors, meeting the most stringent international standards and specifications.

Commited to

Sustainability

Aligned with the Net Zero ambitions of the region, our production lines and processes are designed to reduce environmental impact compared to traditional construction material production. The durability of our products and improved performance decrease maintenance and lifecycle costs.

Our differentiating strengths

Contact information

Corporate Office

P.O. Box 9692

Arab Basalt Fiber Company

Fujairah, United Arab Emirates

Sales Inquiries

Email: [email protected]

Phone: +971 9 6062 229

Technical Support

Email: [email protected]

Phone: +971 9 6062 229

Latest News and Blogs