Product and applications

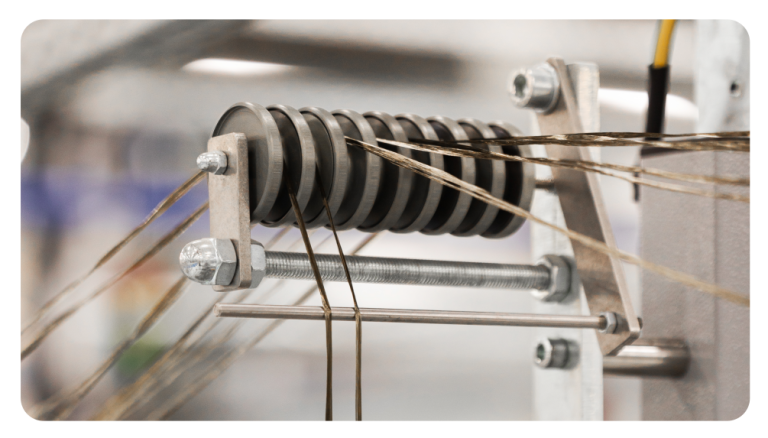

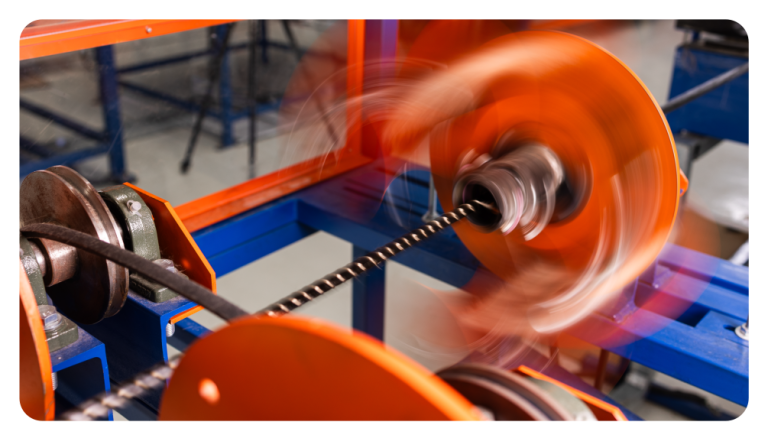

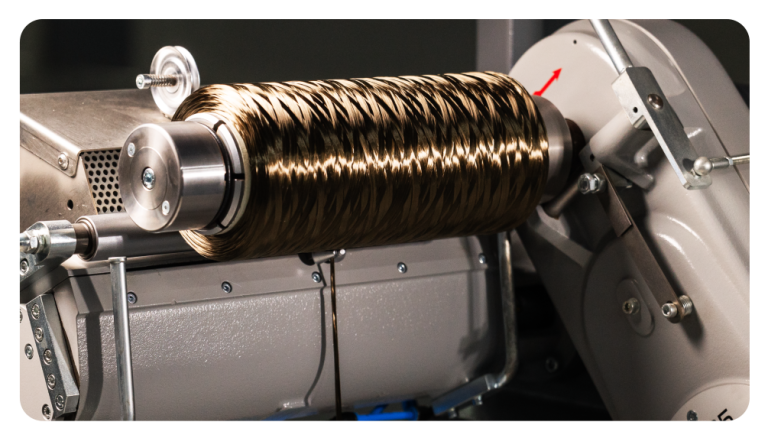

At Arab Basalt Fiber Company, we follow advanced manufacturing processes for basalt fiber production. With materials sourced locally from the Arab Mining Company, we have a rigorous end-to-end quality process that ensures products of the highest standards and specifications.

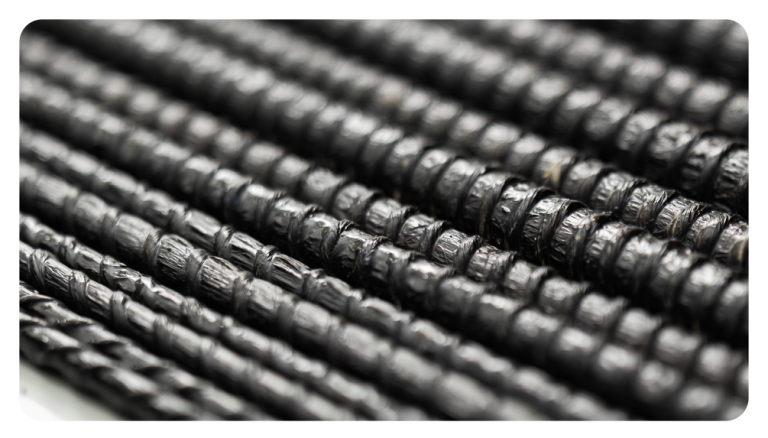

Our BFRP rebars serve specific construction industry needs. The manufacturing process creates reinforcement bars with verified mechanical properties and corrosion resistance. Production capabilities cover diameters from 4mm to 32mm, serving various construction requirements.

The material demonstrates specific advantages in construction applications. Its density measures one-quarter that of steel reinforcement, reducing handling and installation costs. Tensile strength testing shows values 2.5 times higher than conventional steel reinforcement. The material resists corrosion from chlorides and chemical exposure.

Basalt Fiber Rebar

Acclaimed by construction and engineering experts for its anti-rust and anti-corrosion performance, BFRP rebars are today the preferred choice for structures with high levels of exposure to water, such as dams, brdiges and canals. With a strength-to-weight ratio 2.5 times higher than conventional steel reinforcement, they significantly reduce maintenance requirements while extending structural lifecycles.

With production capabilities ranging from 4mm to 32mm diameters, our BFRP rebars are engineered to meet diverse construction requirements while offering substantial cost advantages over traditional steel reinforcement. Serving diverse needs of the industry – from continuous fiber bundles for structural applications and meeting specific manufacturing requirements – our products are customisable to exact reinforcement and specialized applications.

Benefits of Fiber Rebar

Construction Phase

Operational Performance

Utilizing BFRP demonstrate specific sustainability advantages. The material’s durability reduces maintenance requirements. Corrosion resistance eliminates the need for protective treatments. These characteristics support reduced lifetime environmental impact.

Long-term Considerations

Specialized applications

In addition to their use in construction projects across the board, the Arab Basalt Fiber products are used in several specialized applications

Overcome Steel Rebar challenges

with BRFP Rebars

When exposed to moisture and environmental elements, steel reinforcement undergoes oxidation, leading to rust formation that compromises structural integrity.

This corrosion process causes the steel to expand, creating internal pressure leading to concrete cracking, spalling, and eventual structural deterioration. This is particularly challenging in coastal regions, industrial areas, and environments with high humidity levels, where the rate of corrosion is higher. Steel reinforcement deterioration leads to higher costs for infrastructure maintenance and repair in addition to potential disruption in service and environmental challenges. Moreover, the steel production process itself contributes significantly to global CO2 emissions.

Furthermore, steel rebars, being vulnerable to high temperatures, can affect structural integrity, especially during fire incidents. Its high thermal conductivity can affect building energy efficiency too, while its weight increases overall structural loads.Additionally, steel’s electrical conductivity can also pose safety risks in certain applications, limiting its use in specialized construction projects where electromagnetic neutrality is required.

These technical challenges, combined with durability concerns, highlight the need for alternative reinforcement solutions such as BRFP rebars that are designed for modern construction requirements.

Sustainability

We are committed to achieving the region’s Net Zero goals and as such have been focused on limiting our environmental footprint.

Operations: Our facility implements specific environmental control measures. Energy monitoring systems track consumption across production processes, while material recovery programs minimize manufacturing waste and process controls support resource efficiency. Raw material sourcing emphasizes local supply chains helping reduce environmental impacts and emissions, while our processing methods reduce material loss and the water management systems maintain closed-loop operation. These measures support environmental protection goals.

Product: Our products assure specific environmental advantages, with carbon emissions being lower than traditional reinforcement production.

Contact information

Corporate Office

P.O. Box 9692

Arab Basalt Fiber Company

Fujairah, United Arab Emirates

Sales Inquiries

Email: [email protected]

Phone: +971 9 6062 229

Technical Support

Email: [email protected]

Phone: +971 9 6062 229

Latest News and Blogs