Product and applications

With materials sourced locally from the Arab Mining Company, we have a rigorous end-to-end quality process that ensures products of the highest standards and specifications.

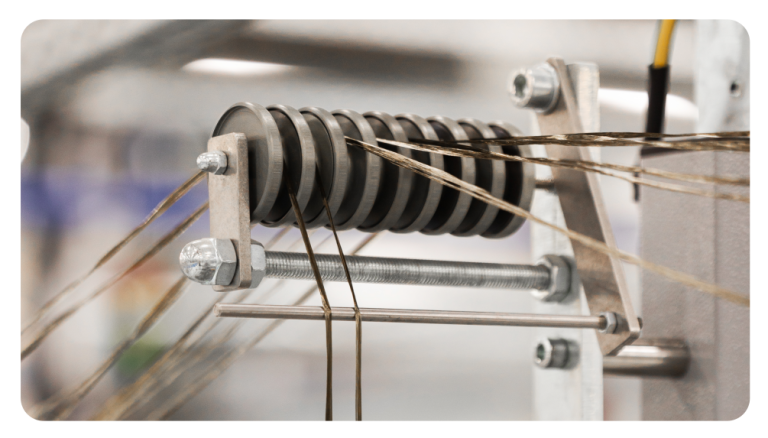

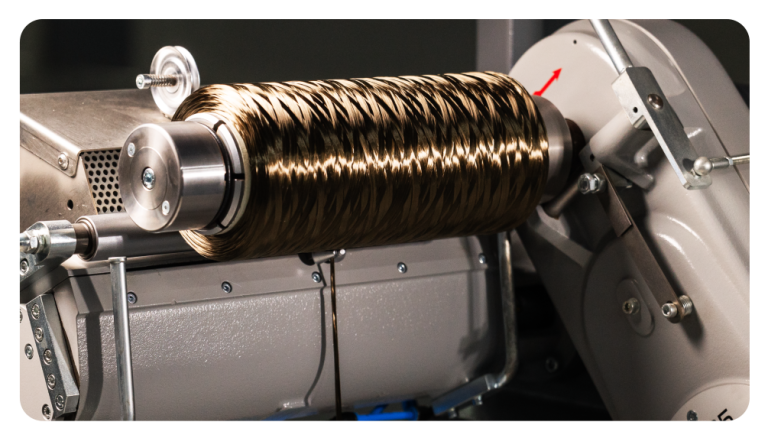

Our process starts with testing basalt rock for mineral composition and structural properties, ensuring consistent raw material quality.Our manufacturing line maintains temperature control between 1400-1600°C, transforming basalt rock into fiber. Advanced monitoring equipment ensures uniform fiber characteristics

Quality verification takes place at all key production stages. Automated systems measure fiber diameter, tensile strength, and surface characteristics, while our advanced laboratory performs additional testing to verify material properties meet specifications.

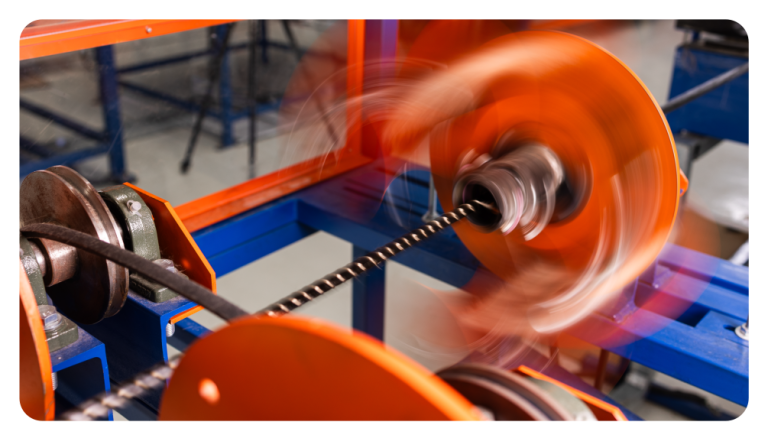

We deploy sophisticated manufacturing processes to create high-performance composites with exceptional mechanical properties, including direct roving with verified tensile strength of 4800 MPa and temperature stability up to 800°C. Our composite manufacturing capabilities extend to diverse product forms, from continuous fiber bundles to specialized fabrics and filaments.

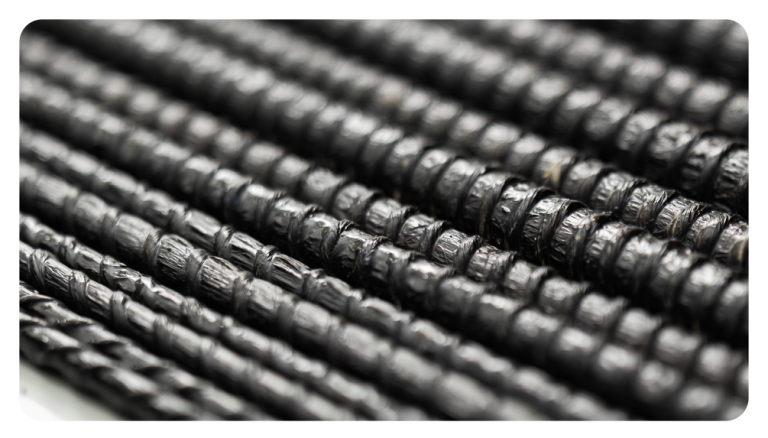

Our BFRP rebars serve specific construction industry needs. The manufacturing process creates reinforcement bars with verified mechanical properties and corrosion resistance. Production capabilities cover diameters from 4mm to 32mm, serving various construction requirements.

The material demonstrates specific advantages in construction applications. Its density measures one-quarter that of steel reinforcement, reducing handling and installation costs. Tensile strength testing shows values 2.5 times higher than conventional steel reinforcement. The material resists corrosion from chlorides and chemical exposure.

Advanced Composite

Our state-of-the-art facility produces advanced composite solutions ideal for multiple industries

The materials demonstrate exceptional performance characteristics, including tensile strength up to 4800 MPa, temperature resistance up to 800°C, outstanding chemical stability, and unique non-conductive and non-magnetic properties.

These advanced composites serve critical applications across key sectors. In automotive manufacturing, they contribute to improved fuel efficiency. The renewable energy sector benefits from superior alternatives for wind turbine components. Military applications utilize these materials for advanced ballistic protection, while the aerospace industry can incorporate our high-performance structural components. Across our product range, we offer comprehensive customization to meet the specific needs of our customers.

Sustainability

We are committed to achieving the region’s Net Zero goals and as such have been focused on limiting our environmental footprint.

Operations: Our facility implements specific environmental control measures. Energy monitoring systems track consumption across production processes, while material recovery programs minimize manufacturing waste and process controls support resource efficiency. Raw material sourcing emphasizes local supply chains helping reduce environmental impacts and emissions, while our processing methods reduce material loss and the water management systems maintain closed-loop operation. These measures support environmental protection goals.

Product: Our products assure specific environmental advantages, with carbon emissions being lower than traditional reinforcement production.

Contact information

Corporate Office

P.O. Box 9692

Arab Basalt Fiber Company

Fujairah, United Arab Emirates

Sales Inquiries

Email: [email protected]

Phone: +971 9 6062 229

Technical Support

Email: [email protected]

Phone: +971 9 6062 229

Latest News and Blogs