Introduction:

In the panorama of construction materials, basalt fiber emerges as a robust and eco-friendly alternative to conventional materials like steel and fiberglass. Heralded for its exceptional properties, such as high tensile strength, resistance to corrosion, and excellent thermal insulation, the applications of basalt fiber stretch far and wide. In this blog, we will delve into various basalt fiber applications, shedding light on how this revolutionary material is reshaping industries.

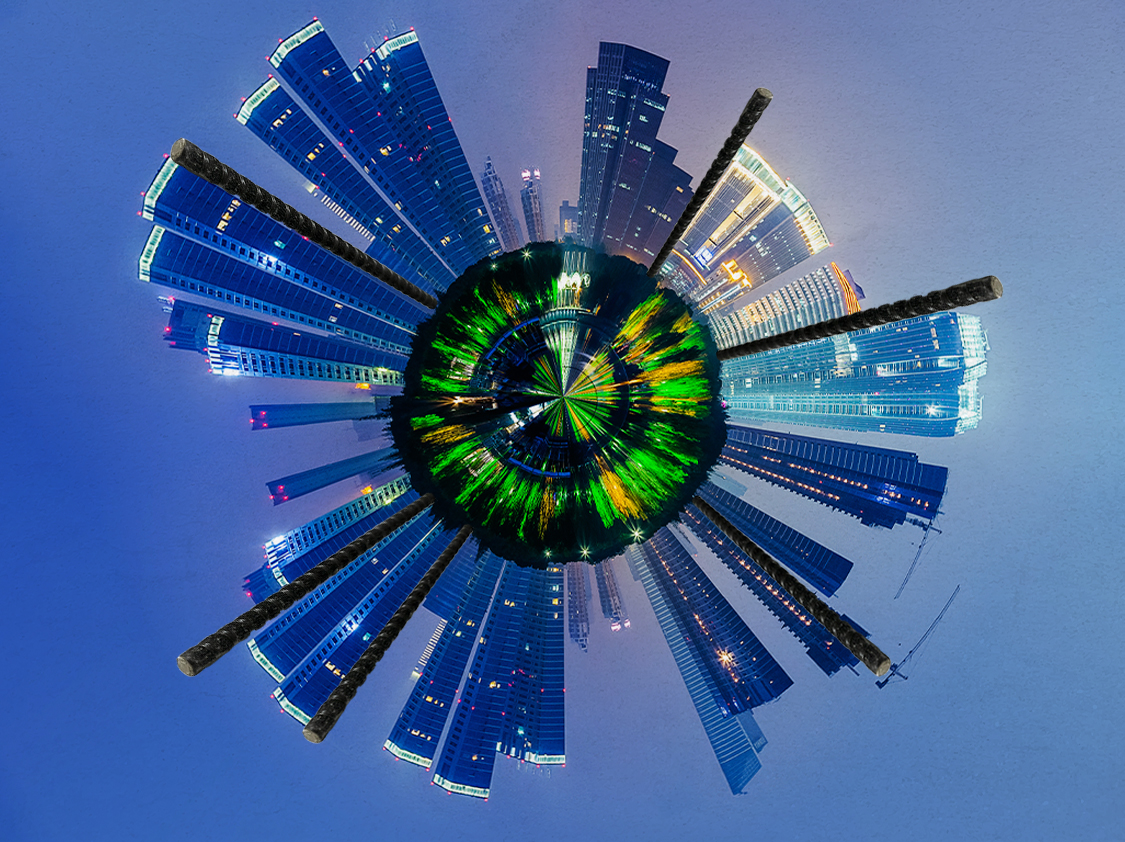

Basalt Fiber Applications in Construction

- Reinforcement Material:

One of the most notable basalt fiber lies in its role as a reinforcement material in construction. The integration of basalt fiber in construction projects enhances the longevity and durability of structures, thanks to its excellent mechanical properties and resistance to environmental factors. Basalt fiber reinforced polymers (BFRP) are increasingly being used to reinforce concrete, replacing traditional steel reinforcements and offering superior strength and corrosion resistance.

- Insulation:

In addition to providing structural strength, another significant application of basalt fiber is in thermal and acoustic insulation. The natural properties of basalt fibers make them an excellent material for insulation purposes, keeping buildings warm in winter and cool in summer, while also providing excellent soundproofing capabilities.

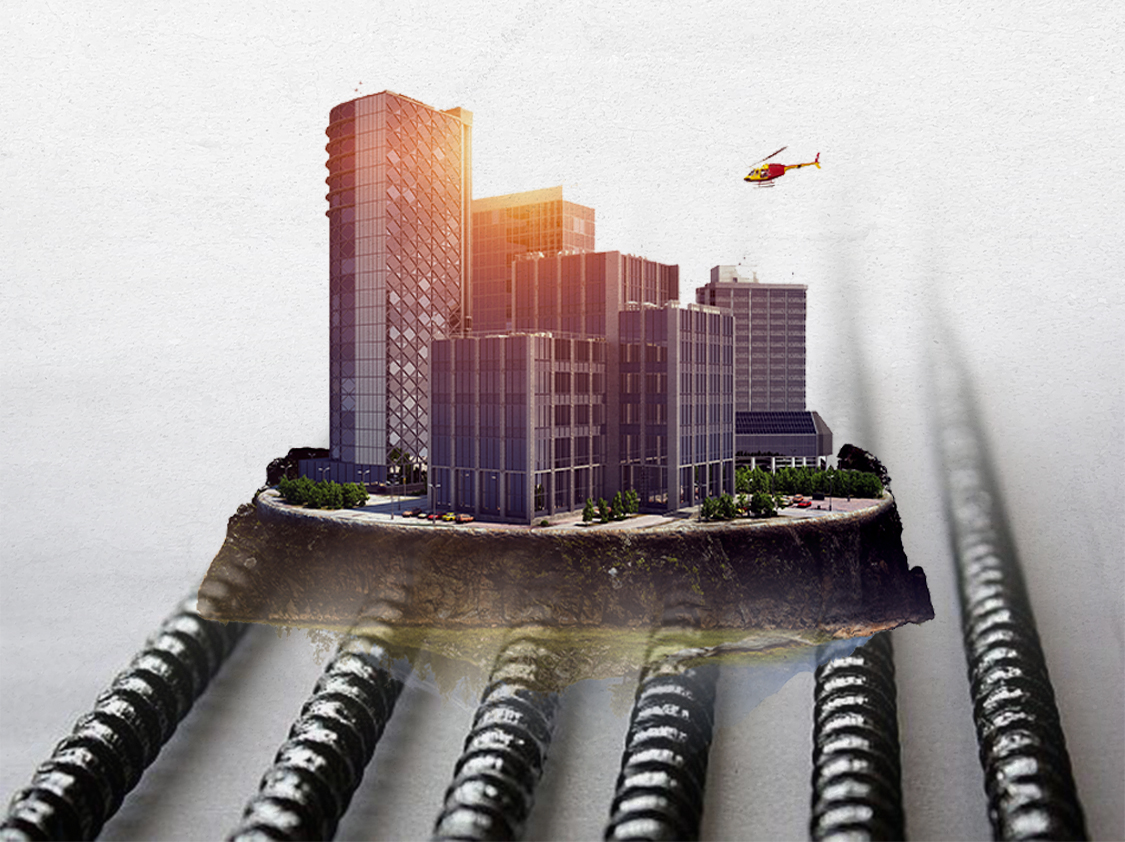

Basalt Fiber Applications in Electronics

• Circuit Boards:

Basalt fiber’s electrical insulation properties have found applications in the electronics industry as well. It’s used in the manufacturing of printed circuit boards, offering better performance and enhanced durability compared to traditional materials.

Basalt Fiber Applications and Environmental Sustainability

• Sustainable Material:

Emphasizing environmental sustainability, fiber applications offer a green alternative to traditional materials. The eco-friendliness of basalt applications resonates with the global shift towards sustainable solutions.

BFRP Rebar has a drastically reduced impact on the environment (10:1) when compared with fiberglass products. This makes it a more sustainable choice for a variety of applications. As well, Basalt fiber is more environmentally friendly when compared to steel production. BFRP Rebar production reduces carbon dioxide emissions by 5.24 tons of coal equivalent per ton. Furthermore, rebar made from Basalt Fiber Reinforced Polymer (BFRP) has less than 74% of the carbon footprint of steel.

• Cost-Effective:

In addition to its environmental advantages, basalt fiber applications also offer economic benefits. Despite the initial investment, the durability and low maintenance requirements of basalt fiber make it a cost-effective material in the long run.

Arab Basalt Fiber Company: Pioneering the Future

Conclusion

The diverse basalt fiber applications across various industries underline the material’s substantial role in driving innovation and sustainability. The continued exploration and adoption of basalt application are pivotal in steering industries towards a future marked by environmental responsibility and robust performance. The extensive range of basalt applications, from construction to electronics, signifies the material’s versatility and its crucial role in shaping a sustainable future.

In the world where basalt applications are revolutionizing industries, the Arab Basalt Fiber Company stands as a beacon of excellence and innovation. Their commitment to advancing fiber applications is unmistakable, contributing significantly to the global emphasis on sustainable and durable materials. By leading initiatives and projects that highlight fiber applications, the Arab Basalt Fiber Company plays a crucial role in propelling the world towards a future where basalt fiber are not just an alternative but a preference in various industrial domains.

For more information about their products and services, please visit their website at www.ArabBasaltFiber.com

or contact them via email: [email protected]