INTRODUCTION

The construction industry in the UAE has been on a rapid rise, with new infrastructure and buildings being built every year. With the need for better and more sustainable reinforcing construction methods, the use of Basalt fiber reinforced polymer (BFRP) has been gaining popularity in the country.

The BFRP construction material has gained increasing popularity in recent years due to its excellent mechanical properties, including its strength, durability, and corrosion resistance. As a sustainable and cost-effective alternative to traditional materials, BFRP is finding applications in various fields of construction in the UAE. This article explores the benefits, applications, factors affecting prices, and the role of Arab Basalt Fiber Company in the UAE market.

THE BENEFITS OF BFRP

BFRP offers many advantages over traditional construction materials such as steel. Here are the key benefits:

- BFRP has a significantly lower carbon footprint than glass fiber rebar and steel, with less than 1/10th the carbon footprint of glass fiber rebar and 74% less than steel.

- Basalt fiber is lightweight, weighing 4.5 times less than steel, which makes it easier to transport and install.

- BFRP has 2.5 times greater tensile strength than steel, offering superior durability with a lifespan of over 100 years.

- BFRP reduces concrete coverage by 25-30%, saving concrete and providing lightweight construction.

- BFRP enhances job site safety due to its lightweight and easy-to-handle material.

- Basalt fiber is cost-effective, eliminating costly maintenance and repairs associated with traditional steel reinforcement.

- BFRP is 100% non-corrosive, resistant to alkaline and seawater, and water-resistant.

- Basalt fiber is highly resistant to fire, capable of withstanding high temperatures (up to 700 C) without igniting.

- Basalt fiber has excellent thermal insulation properties, contributing to improved energy efficiency in buildings.

- Basalt fibers are highly versatile and suitable for a wide range of Reinforcing Construction applications due to their superior physical and chemical properties.

APPLICATIONS OF BFRP IN THE UAE

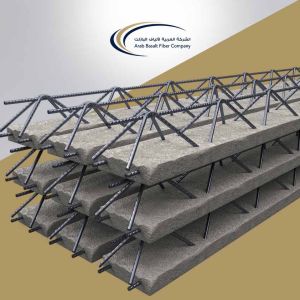

Basalt Fiber Reinforced Polymer (BFRP) has several applications in the construction industry in the UAE, including reinforced concrete, structural strengthening, and retrofitting.

- Reinforced Concrete:

BFRP can be used as an alternative to steel reinforcement in reinforced concrete structures. Its lightweight and high tensile strength make it ideal for use in concrete beams, slabs, and columns. BFRP rebar BFRP rebar has the ability to reduce concrete coverage by 25 – 30%, as opposed to traditional steel reinforcement that requires a minimum of 4 cm of concrete coverage to keep it safe. With BFRP rebar, the covering layer can be reduced to just 1 cm, which can help save concrete and provide a more sustainable and cost-effective construction solution. - Structural Strengthening:

Structural strengthening is the process of adding additional support to an existing structure to improve its load-carrying capacity. BFRP plates and laminates can be used to strengthen and reinforce concrete, masonry, and timber structures. BFRP laminates can be easily installed and can help to increase the strength and durability of the structure. - Retrofitting:

Retrofitting involves the modification of an existing structure to improve its performance or adapt it to a new use and to meet modern safety and structural standards. BFRP can be used for retrofitting structures such as bridges, tunnels, and buildings. BFRP laminates can be used to increase the load-carrying capacity of beams and columns, while BFRP plates can be used to reinforce walls and slabs.

REAL EXAMPLES OF BFRP REBAR-BASED CONSTRUCTIONS IN UAE

Basalt Fiber Reinforced Polymer (BFRP) rebars have been increasingly used in the construction industry in the UAE. Burj Khalifa is a real example of BFRP rebar-based Reinforcing Construction in the UAE.

Burj Khalifa, is a super-high skyscraper with a height of 828 meters in Dubai (UAE). It is the tallest and most multistory building, the tallest structure, the only 828-meter and 163-storey skyscraper in the world.

As part of the construction of this magnificent tower, high-quality basalt Fiber was used to reinforce the interior cladding panels for the interior of this building.

Additionally, basalt fiber is used to construct the dome of the Louvre Abu Dhabi, as it is able to withstand harsh weather conditions and provides excellent insulation.

FACTORS AFFECTING BFRP PRICES IN THE UAE

Several factors can influence the prices of BFRP (Basalt Fiber Reinforced Polymer) in the UAE. Here are some of the most significant factors affecting BFRP prices in the UAE:

- Raw Material Costs: The cost of producing BFRP is heavily influenced by the cost of its raw materials, including basalt fiber, epoxy resin, and curing agents. In the UAE, these materials are easily accessible at reasonable prices, particularly in the Emirates of Fujairah, where the Arab Basalt Fiber Company is located. Basalt stones are in ample supply in Fujairah, making them an affordable raw material for BFRP production.

- Manufacturing Process: The manufacturing process for BFRP involves several stages, including fiber production, resin formulation, and the actual fabrication of the product. The cost of labor, energy, and equipment involved in these processes can affect the price of the final product. However, Arab Basalt Fiber Company employs the latest technology, which is not only cost-effective but also environmentally friendly, resulting in reduced manufacturing costs for BFRP. This allows them to offer BFRP products at a competitive price without compromising quality.

- Market Demand: The demand for BFRP products can impact on the price of the material. Higher demand typically leads to higher prices, while lower demand can result in lower prices. However, Arab Basalt Fiber Company has plans to increase its production capacity from 5000 tons to 10,000 tons in the coming years, which will help meet the growing market demand for BFRP products. As a result, this expansion will enable the company to maintain its competitive prices, despite the expected increase in demand.

- Availability: The availability of BFRP products in the UAE can also influence their price. If BFRP products are readily available, their price may be lower. However, if they are scarce or have to be imported from other countries, their price may be higher due to transportation costs and import taxes.

- Certification and Quality Standards: BFRP products must meet certain certification and quality standards to be used in construction projects. These standards ensure that the product is safe and meets performance expectations. Higher certification and quality standards can increase the cost of the product.

THE ROLE OF ARAB BASALT FIBER COMPANY IN THE UAE MARKET

Arab Basalt Fiber Company is one of the leading suppliers of BFRP in the UAE. The company offers a range of high-quality products at competitive prices, making it an ideal choice for construction companies looking to incorporate BFRP in their projects.

The Arab Basalt Fiber Company is a leading producer and supplier of high-quality basalt fiber products in the UAE market. The company has quickly gained recognition and popularity among construction industry professionals for its reliable and innovative solutions.

The company offers BFRP rebar and some other structural elements. These products are manufactured using state-of-the-art technology and strict quality control procedures to ensure the highest standards of performance and durability.

Arab Basalt Fiber Company role in the UAE market is crucial in promoting the use of basalt fiber reinforced products as a sustainable and cost-effective alternative to traditional construction materials. The company works closely with engineers and contractors to develop customized solutions that meet specific project requirements and maximize the benefits of BFRP. To know about BFRP uses click here.

One of the key advantages of working with Arab Basalt Fiber Company is their commitment to innovation and continuous improvement in Reinforcing Construction. The company invests heavily in research and development to improve the performance and versatility of their products, and to explore new applications and markets for basalt fiber. This has enabled Arab Basalt Fiber Company to stay ahead of the competition and maintain a leading position in the UAE market.

Overall, the Arab Basalt Fiber Company plays a critical role in promoting the use of basalt fiber reinforced products in the UAE market. Their commitment to quality, innovation, and sustainability has earned them a reputation as a trusted and reliable partner for construction industry professionals.

CONCLUSION

The use of BFRP in the UAE is on the rise, and for good reason. With their excellent mechanical properties and resistance to corrosion, BFRP are an ideal choice for Reinforcing Construction of concrete structures, structural strengthening, and retrofitting projects. While the initial cost may be higher than traditional steel reinforcement, the long-term cost savings and durability make them a worthwhile investment for the Reinforcing Construction industry in the UAE.