INTRODUCTION:

Basalt fiber technology is shaping the future of sustainable construction and manufacturing. As industries seek eco-friendly alternatives, this technology stands out for its environmental and mechanical advantages, marking a significant shift towards green practices.

Manufacturing Process of Basalt Fiber:

The process behind Basalt fiber technology is precise, ensuring the transformation of natural basalt rock into a strong composite material.

- Quarrying: Basalt fiber technology begins with the mining of basalt rock from volcanic deposits, a testament to its natural origin.

- Crushing: Small fragments are produced from the mined rock, making it amenable to processing.

- Melting: At 1,400-1,600°C, the crushed basalt melts, paving the way for fiber formation.

- Extrusion: Molten basalt is then extruded through fine nozzles, creating continuous fibers.

- Winding and Processing: Rapidly solidifying upon air contact, the fibers are wound and processed into various formats, integral to Basalt fiber technology applications.

Advantages of Basalt Fiber:

Utilizing Basalt fiber technology yields products with unparalleled benefits:

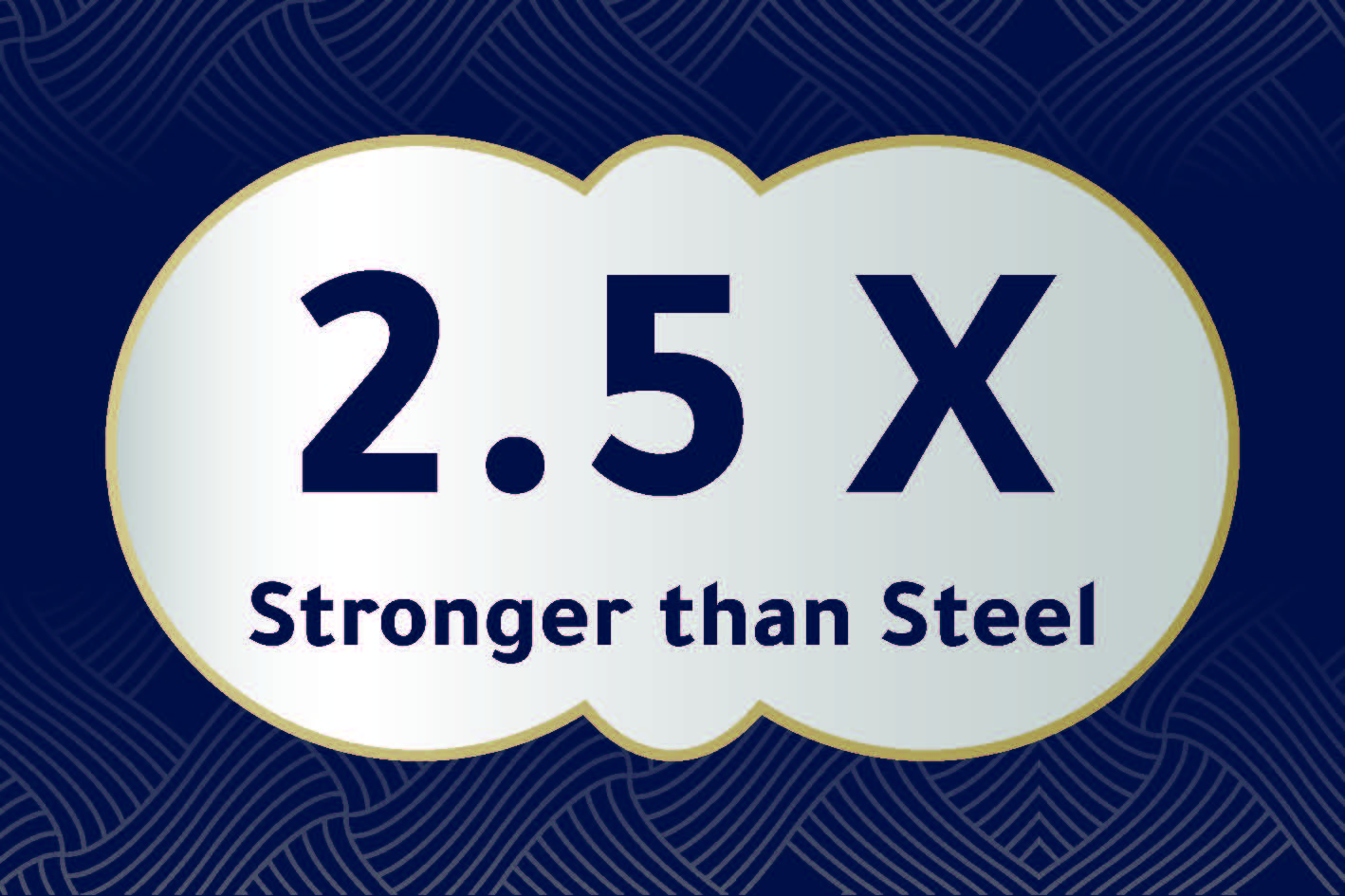

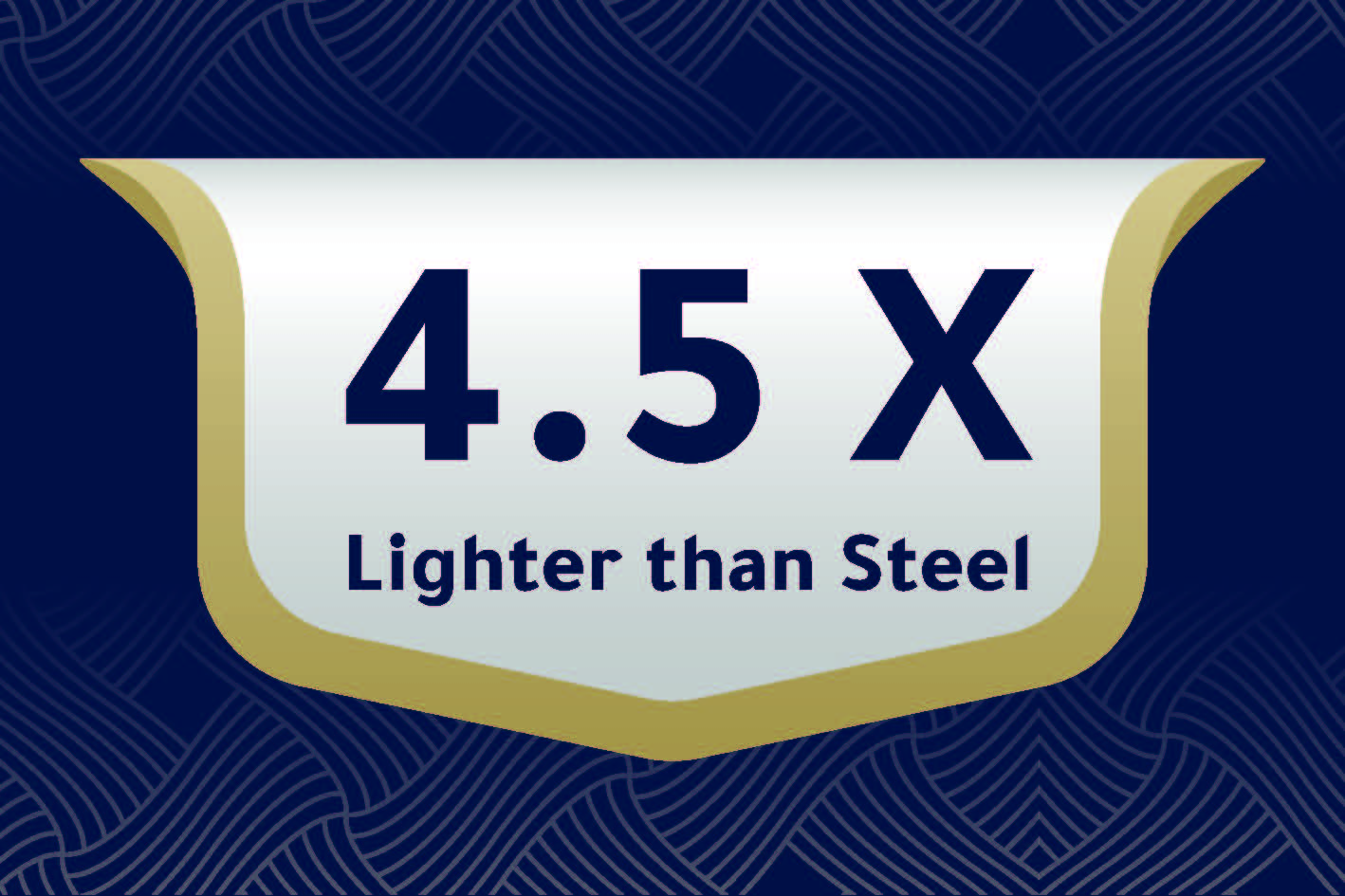

- Tensile Strength: Basalt fiber technology boasts tensile strength comparable to or exceeding steel, carbon, and glass fibers, leading to more efficient structures. The BFRP rebar, notably lighter yet stronger than steel, is transforming load-bearing applications.

Fact: “The weight of BFRP Rebar is 4.5 times lighter than steel, while its tensile strength is 2.5 times that of steel”

- Corrosion Resistance: In stark contrast to steel, basalt fiber is impervious to rust and corrosion, making it ideal for harsh environmental conditions and reducing long-term maintenance costs.

- Thermal Stability: Basalt fiber’s resilience at temperatures up to 800°C makes it a prime candidate for fireproofing and insulation, ensuring integrity in extreme conditions.

- Electromagnetic Neutrality: Free from electromagnetic interference, Basalt fiber technology is perfect for use in telecommunications and aerospace, where such neutrality is crucial.

- Fatigue Resistance: The superior fatigue resistance of basalt fibers allows for sustained performance under repetitive stress, lessening the likelihood of failure in high-stress environments.

Advantages of Basalt Fiber:

Utilizing Basalt fiber technology yields products with unparalleled benefits:

- Tensile Strength: Basalt fiber technology boasts tensile strength comparable to or exceeding steel, carbon, and glass fibers, leading to more efficient structures. The BFRP rebar, notably lighter yet stronger than steel, is transforming load-bearing applications.

Fact: “The weight of BFRP Rebar is 4.5 times lighter than steel, while its tensile strength is 2.5 times that of steel”

- Corrosion Resistance: In stark contrast to steel, basalt fiber is impervious to rust and corrosion, making it ideal for harsh environmental conditions and reducing long-term maintenance costs.

- Thermal Stability: Basalt fiber’s resilience at temperatures up to 800°C makes it a prime candidate for fireproofing and insulation, ensuring integrity in extreme conditions.

- Electromagnetic Neutrality: Free from electromagnetic interference, Basalt fiber technology is perfect for use in telecommunications and aerospace, where such neutrality is crucial.

- Fatigue Resistance: The superior fatigue resistance of basalt fibers allows for sustained performance under repetitive stress, lessening the likelihood of failure in high-stress environments.

Basalt Fiber Technology in Industrial Applications:

Basalt fiber is revolutionizing several industries. The construction sector is leveraging fiber technology for reinforcing concrete, thereby enhancing the longevity and durability of structures. In the automotive industry, Basalt technology is being employed to create components that are lightweight yet robust, improving fuel efficiency and reducing emissions.

Challenges and Future of Basalt Fiber Technology:

Despite its many benefits, Basalt fiber faces challenges, particularly in terms of production scalability. Nevertheless, ongoing advancements in Basalt fiber are addressing these issues, broadening the scope of its applications. As Basalt technology continues to evolve, its role in the future of sustainable materials looks promising.

Conclusion:

Basalt fiber technology is not just a material; it’s a key to unlocking a sustainable and efficient future in construction and beyond. From the quarry to the finished composite, Basalt fiber stands as a beacon of innovation, promising to underpin many of tomorrow’s infrastructural marvels.

Basalt Fiber Technology in Industrial Applications:

Basalt fiber is revolutionizing several industries. The construction sector is leveraging fiber technology for reinforcing concrete, thereby enhancing the longevity and durability of structures. In the automotive industry, Basalt technology is being employed to create components that are lightweight yet robust, improving fuel efficiency and reducing emissions.

Challenges and Future of Basalt Fiber Technology:

Despite its many benefits, Basalt fiber faces challenges, particularly in terms of production scalability. Nevertheless, ongoing advancements in Basalt fiber are addressing these issues, broadening the scope of its applications. As Basalt technology continues to evolve, its role in the future of sustainable materials looks promising.